Large glass walls, also referred to as Curtain Walls, have become a hallmark of city style architecture and residential design where access to natural light and abundant views are desired. With our innovative 4F steel Curtain Wall system, we are able to provide dramatic glass walls with exceptional thermal performance in a full range of exceptional materials and finishes without compromising the sight-line.Additionally, 4F can be integrated with our entire collection of thermally broken steel window and door systems to produce a system that is simply unmatched in comfort, style and maintainability.

MATERIAL & FINISH OPTIONS

If you are familiar with our products than you are already aware that our quality and diversity in materials and finish options are nothing less than superior. Similar to our other thermally broken products, both the 4F1 & 4F2 Curtain Wall series are available in Painted Galvanized Steel, 304 & 316L Stainless Steel, and Cor-Ten. Due to the properties of Bronze, it is only offered as an option for the exterior cover but not the interior structural mullion.

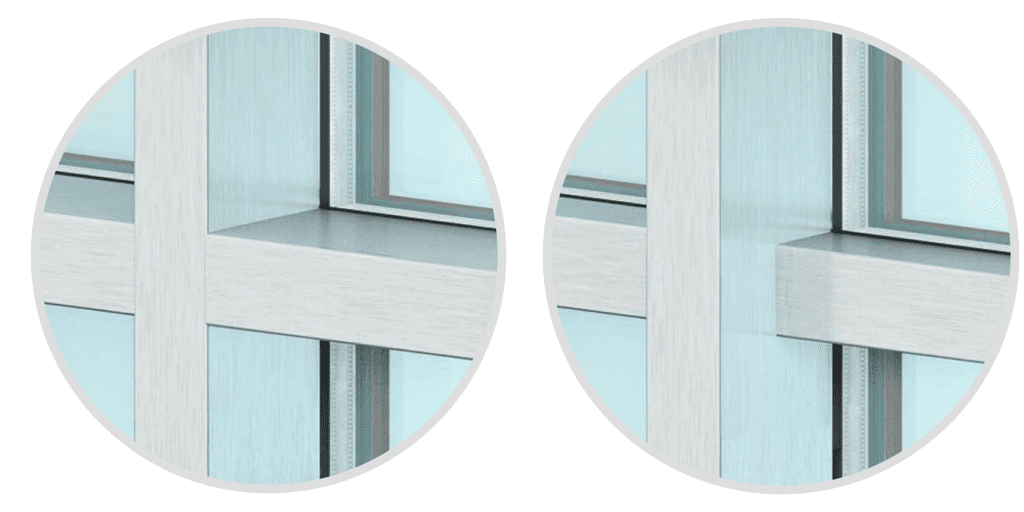

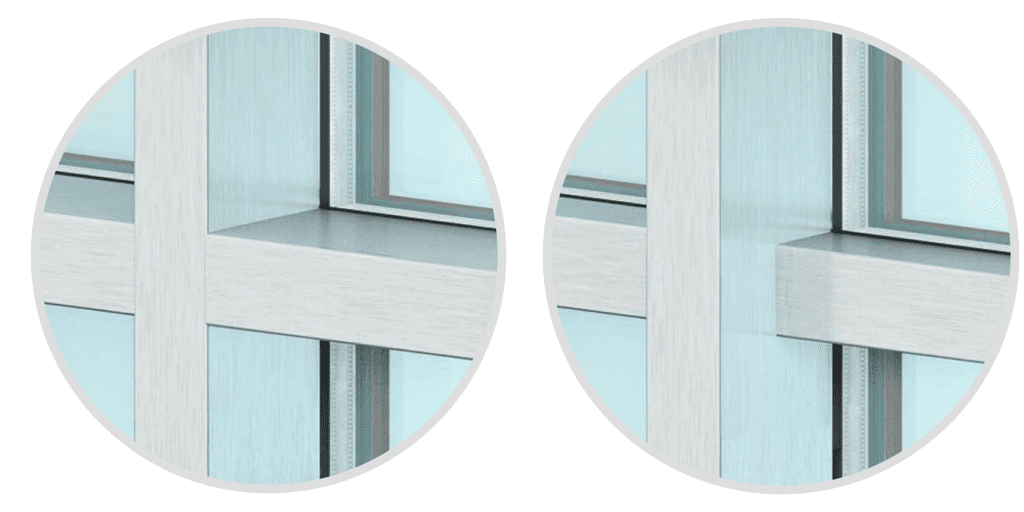

MULLION STYLES

The two standard mullion styles are the Recessed 2” (50mm) style, which is detailed on the far left, and the Flush 4” (100mm) style, which is detailed on the right. To stay ahead of the increasing demand for larger openings in the residential and commercial architecture, the 4F1 series was engineered with steel mullions that achieve a remarkably high moment of inertia to meet the static load requirements without compromising the aesthetic style or quality of the materials.

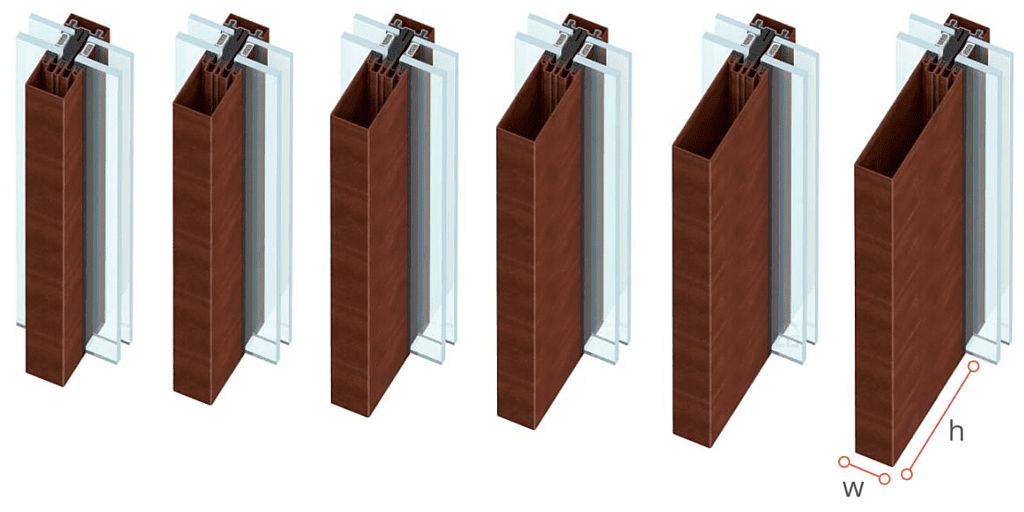

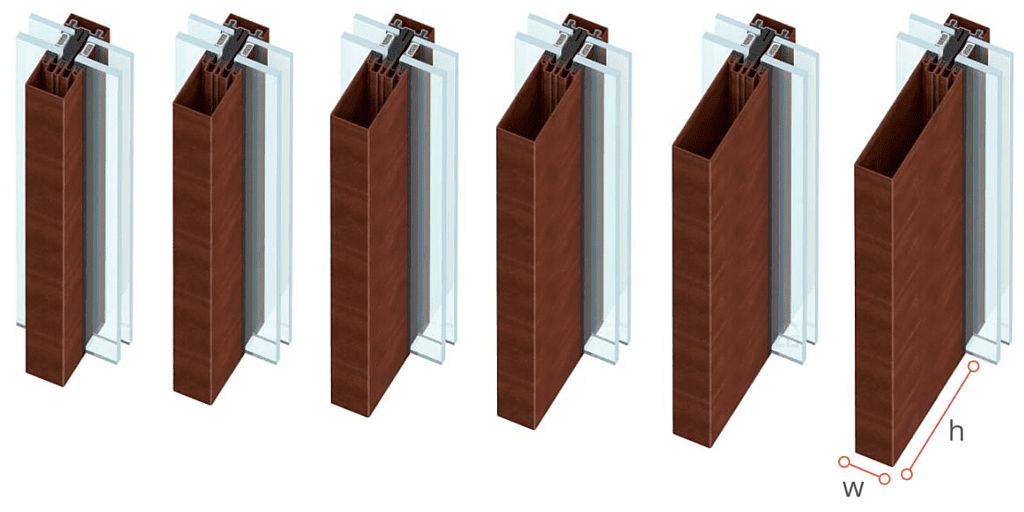

MULLION & TRANSOM SIZES

The standard width (w) dimension for all mullion/transom sections in the 4F1 series is 2″ (50mm) but the height (h) is available in six different sizes ranging from 2″ (50mm) to 7″ (180mm). The varying mullion height options allows the designer or architect the possibility to increase the overall size of the glass wall without additional intermediate structural mullions – therefore providing a much larger continuous glass surface without compromising the viewing experience.

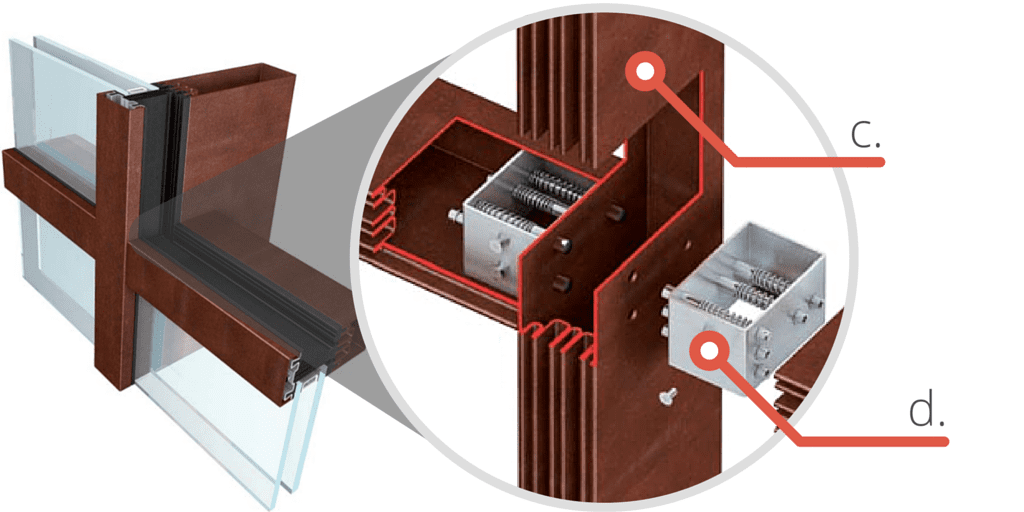

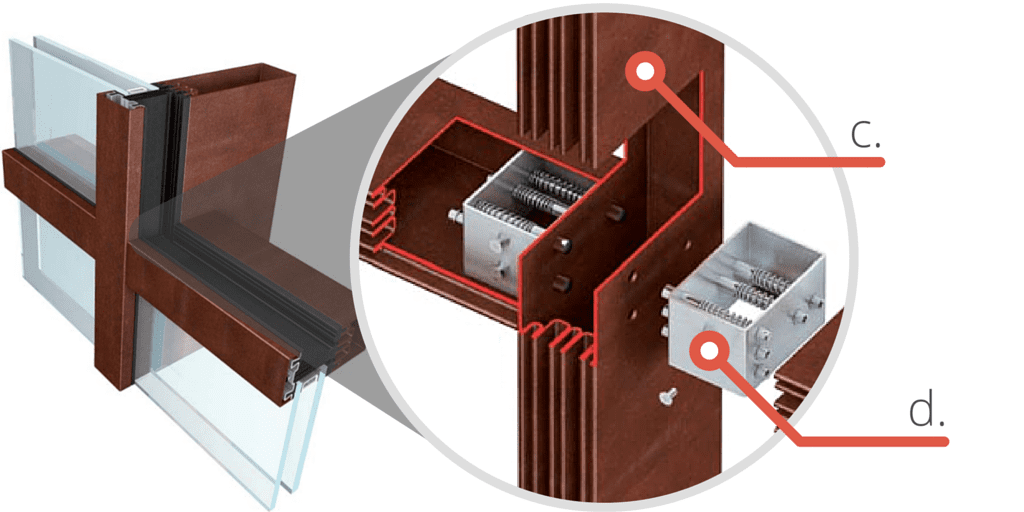

LOAD-BEARING SUBSTRUCTURE

The detail to the left shows a sectional view of the the structural mullion (c) as well as the integrated spring loaded coupling device (d). A key benefit of the 4F1 Curtain Wall system is its ability to hide the individual connections between the load bearing mullions to create a seamless visual transition throughout the entire wall. Additionally, the internal coupling component allows for a much smoother and reliable installation and/or disassembly procedure.

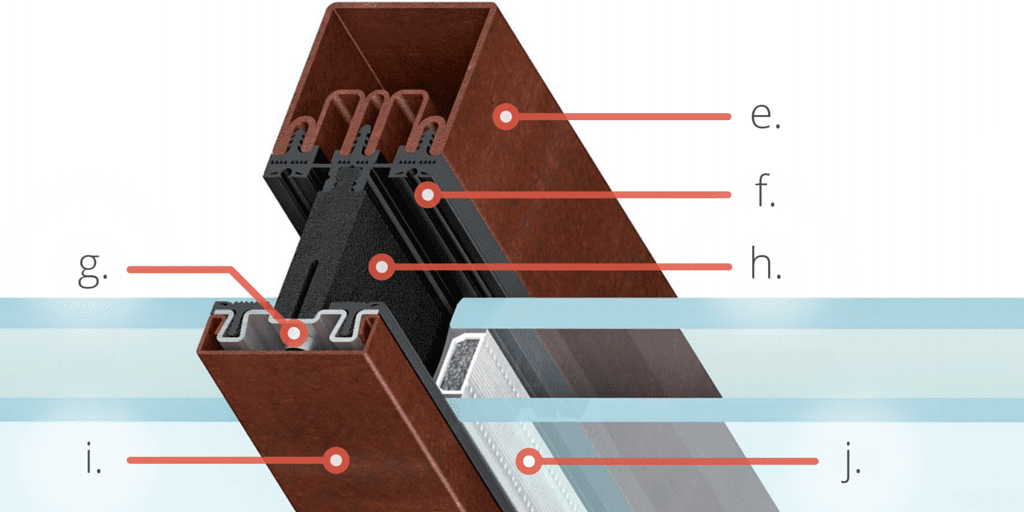

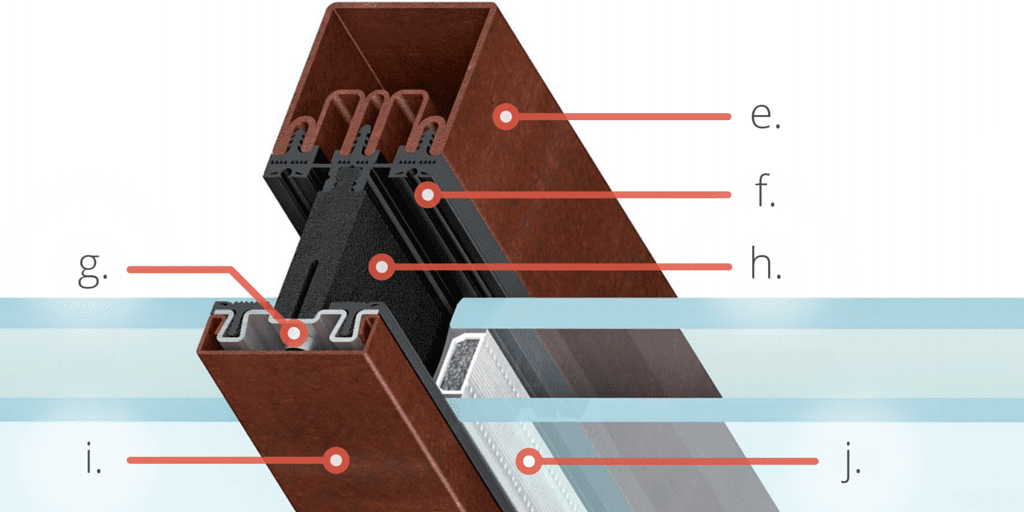

ASSEMBLY OVERVIEW

On the right is a detailed assembly view of the 4F1Curtain Wall system which highlights key elements such as the: structural load-bearing mullion (e), weather tight EPDM gaskets (f), pre-drilled securement plate with integrated weather tight EPDM gaskets (g), closed-cell polyethylene thermal barrier (h), exterior glazing cover (i), and the insulated glazing pocked for glass thickness up to 2 3/16” or 56mm (j).

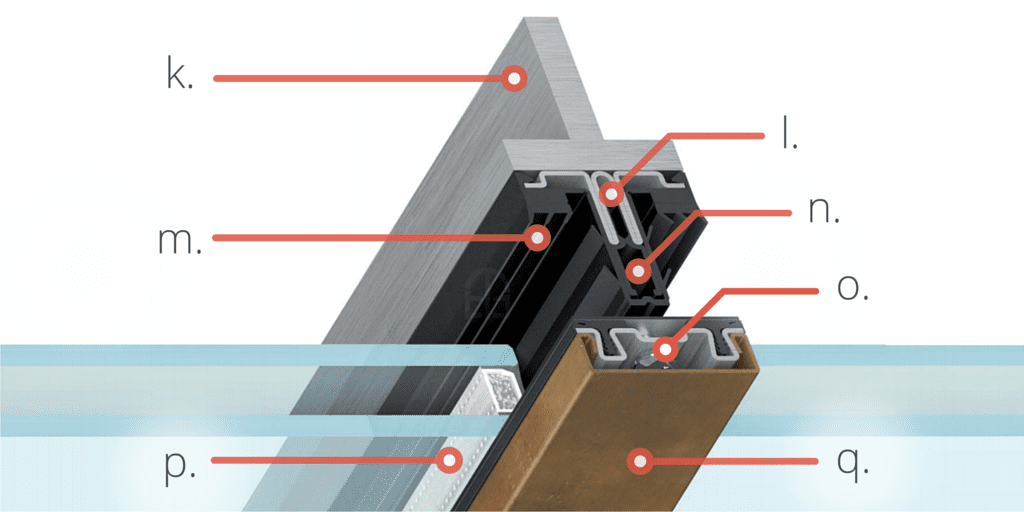

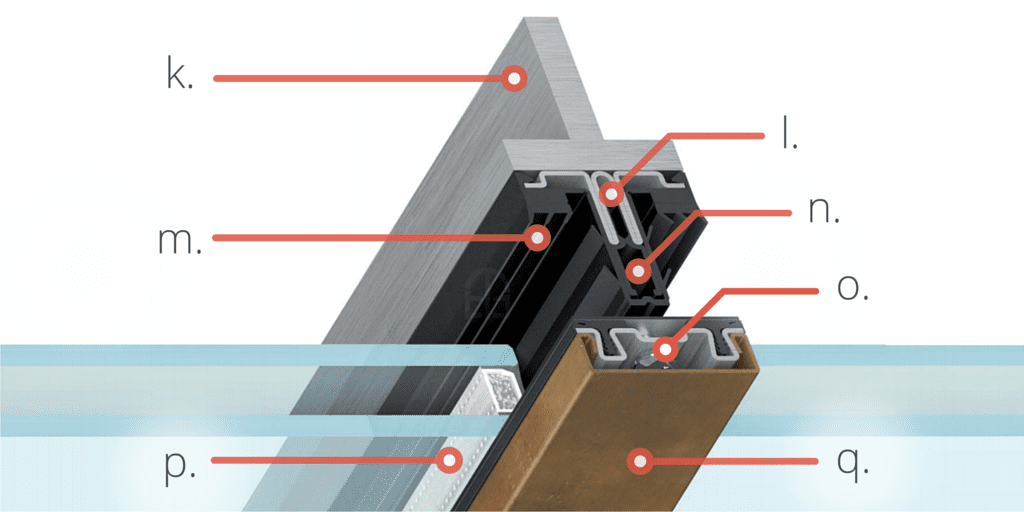

ASSEMBLY OVERVIEW

On the left is a detailed assembly view of the 4F2 Curtain Wall system which highlights key elements such as the: exsisting load-bearing support (k), integrated substructure (l), weather tight EPDM gasket system (m), variable thermal barrier (n), pre-drilled securement plate with integrated weather tight EPDM gaskets (o), insulated glazing pocked for glass thickness up to 2” or 50mm (p), and the exterior glazing cover (q).